- Home

- Sustainability

- Environment

Environment

Initiatives to tackle environmental issues

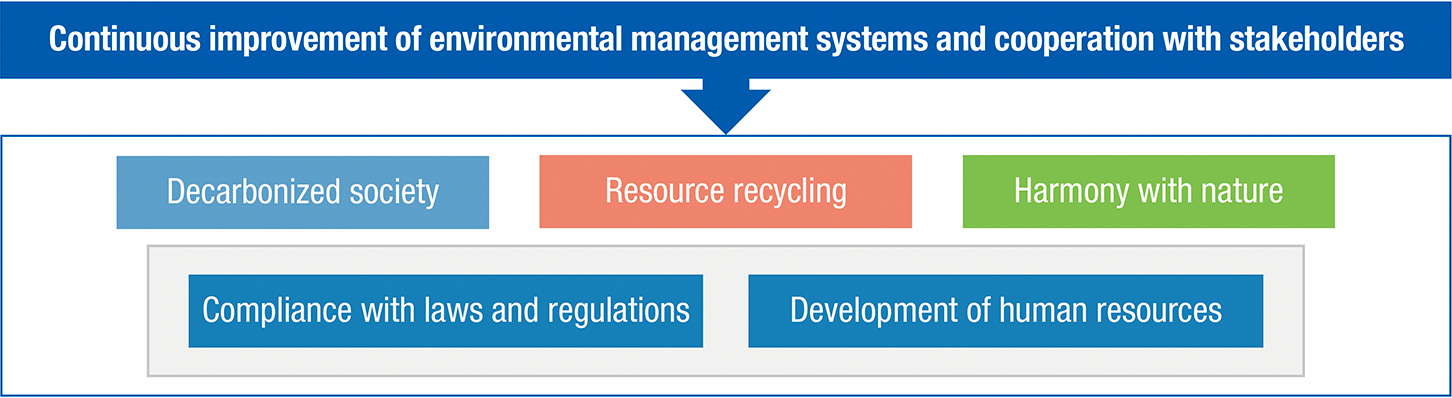

The Group set mid-term environmental goals to achieve by 2025 for three issues: decarbonized society, resource recycling, and harmony with nature. We are pursuing specific initiatives to achieve these goals. Climate change is a globally important task, and we need to take long-term initiatives. We are taking action with the aim of achieving carbon neutrality by 2050.

Environmental Philosophy and Policy

Environmental Philosophy

We have established the Environmental Philosophy and Policy as Group-wide policies on environmental issues. Based on these policies, we will continue our efforts to improve environmental issues.

Environmental Policy

[Issued following the approval by senior management in July, 1993. Revised in October, 2017.]

- Preface -

Foster Group aims to contribute for “Decarbonized society”, “Resource recycling” and “Harmony with nature”, by pursuing eco-friendly technologies in the lifecycle of our products, and people of Foster Group act with priority on eco-friendliness.

- We contribute to the realization of a sustainable society by continually improving our environmental management systems, and by communicating and cooperating with our stakeholders proactively.

- Realization of “Decarbonized society”

We reduce CO₂ emissions throughout our value chain including procurement of raw materials, manufacturing, transportation, selling and disposal of our products. - Realization of “Resource recycling”

We strive for the waste reduction by promoting effective use of resources in our group-wide activities and product development.

We also use water resources responsibly in our manufacturing processes. - Realization of “Harmony with nature”

We strive for the promotion of activities considering Biodiversity conservation, prevention of pollution and environmental load reduction by chemical substance management. - We comply with domestic and international environmental laws and regulations and other requirements related to our group-wide activities.

- We develop human resources who practice environmental activities through enlightening people involved in group activities and educating employees.

【Issued following the approval by senior management in July 1993. Revised in March 2021.】

Mid-Term Environmental Goals 2025

To achieve the mid-term environmental goals 2025 that we set in 2020, we continue activities to reduce the environmental load from a lifecycle perspective, by working together with manufacturing sites.

| Goals | 2020 - 2025 | |

|---|---|---|

| Decarbonized society | CO2 emissions reduction (Scope1,2,3) | Scope 1, 2: Reduce absolute CO2 emissions by 30% from a FY2018 base year |

| Scope 3: Reduce absolute CO2 emissions 3% from a FY2018 base year | ||

| Resource recycling | Resource saving products | - Establish technology for eco-friendly products |

| Improvement of production process | - Reduce the hazardous waste generated by 5% from a FY2018 base year | |

| - Reduce water consumption (Efficient use of water resource) | ||

| Harmony with nature | Management of chemical substances | - Build global management system based on the company standards and regulations |

| Biodiversity conservation | - Establish a biodiversity policy and the mid-term action plan | |

| Partnership with stakeholders | - Build a cooperative structure and implementation of activities with our suppliers | |

Environmental Activities

Activities to Preserve Biodiversity

We have set “Biodiversity conservation” as one of the tasks for “Harmony with nature,” a mid-term environmental goal, and continue to hold lecture meetings and training on biodiversity, sessions for observing the immediate natural environment, and neighborhood cleanup activities. Currently we began to prepare for information collection and other initiatives for disclosing information based on the recommendations of the Task Force on Nature-related Financial Disclosures (TNFD).

Water Risk Management

Each site manages water withdrawal and discharge by setting their standards based on local laws and regulations. The headquarters uses “AQUEDUCT”, a water risk assessment tool of the World Resources Institute (WRI), to understand the local water risks at each site. Since 2020, we have been addressing water risks by including “Reduce water consumption” in the mid-term environmental plan.

Chemical Substance Management

The Group has set forth its autonomous management standard, which reflects the applicable laws and regulations of countries, including the RoHS Directive and REACH regulations, and customers’ requests for handling environmentally hazardous substances contained in its products to minimize their impact on the environment. We eliminate any controlled substances from our products via eco-friendly procurement and management of necessary parts and/or materials purchased. Based on the aforementioned scheme, we have established an optimum management system for the efficient search and collection of information about chemical substances that are contained in parts and materials and precise communication of information necessary in the supply chain.

In addition, to ensure communications of related information, we provide our suppliers with briefing meetings every year primarily at our overseas sites.

Environment Management System and ISO 14001 Certification

We have obtained ISO 14001 certifications at headquarters and all of our overseas manufacturing sites and embody the Foster Group's Environmental Philosophy and mid-term environmental goals. At headquarters, we monitor the activities conducted at each site and check their results.

The Foster Group's Environmental Initiatives

Effective utilization of water resources

One of our strengths is the in-house production of diaphragms, which are the most important parts of speakers in determining the sound quality. However, the papermaking process is a necessary part of manufacturing the paper parts used in these diaphragms. This process uses a large amount of water as paper is made from raw materials dissolved in water. At the headquarters and the Panyu Factory (China), we have been studying the reuse of discharged water for many years. As of December 31, 2023, 60% of the water used in the papermaking process is recycled water, allowing us to effectively utilize this resource.

We have also been considering the recycling of the paper raw materials collected during the wastewater recycling process. We are using them for paper ring subcomponents and other purposes, enabling us to recycle 6% of the waste materials. Moving forward, we will take inspiration from the reuse of waste materials in industries such as clothing to incorporate waste materials into our diaphragms and other components, further reducing waste.

Final filtration tanks

Intermediate treatment

After treatment

Participation in the Akishima City Community Development Corporate Summit

In December 2023, we participated in the 2nd Akishima City Community Development Corporate Summit hosted by Akishima city. This second summit was themed on the “Environment”, and we exchanged opinions with neighboring companies and reported our activities related to community development through public-private partnerships towards the realization of a carbon-neutral city.

Initiatives at our headquarters building

Our headquarters employs environmental load reduction technologies such as lighting control by daytime sunlight, air conditioning by outside air, ice thermal storage air conditioning system, and doubleskin facade. Electricity consumption is controlled further by limiting maximum power consumption during the day, promoting Cool Biz and Warm Biz campaigns, turning off all the lights in the building for lunch breaks, and promoting the replacement of all of the lights in building with LEDs. In September 2024, we will begin to use electricity certified as coming from renewable energy power plants* and all of the electricity consumed at the headquarters is expected to come from renewable energy sources.

* Electricity using Non-Fossil Certificates (with renewable energy specified as the sources) which is 100% virtually from renewable sources of energy and whose actual CO2 emission factor is zero

Lighting control by daytime sunlight

Introduction of electronic waste manifests in Japan

The waste manifest (industrial waste control form) system enables generators of industrial waste to track and manage the process of industrial waste from its generation to the final disposal. The electronic version of this system is called an electronic manifest. The introduction of this system streamlines administrative processes, ensures data transparency, and prevents illegal dumping, allowing waste generators to fulfill their responsibilities. Centralized management also leads to the strengthening of legal compliance.

External communications

Green Value Chain platform

As a corporate member, we participate in a network for promoting Green Value Chains (available in Japanese)as part of the Ministry of the Environment’s Green Value Chain Platform.

Japan Climate Initiative (JCI)

In 2020, we joined the Japan Climate Initiative (JCI) (available in Japanese)by agreeing to its declaration of “Joining the front line of the global push for decarbonization from Japan”.

Environmental Digital Platform

In March 2023, we joined the Environmental Digital Platform (available in Japanese) operated by Konica Minolta, Inc.

Environmentally Friendly Products

Speakers

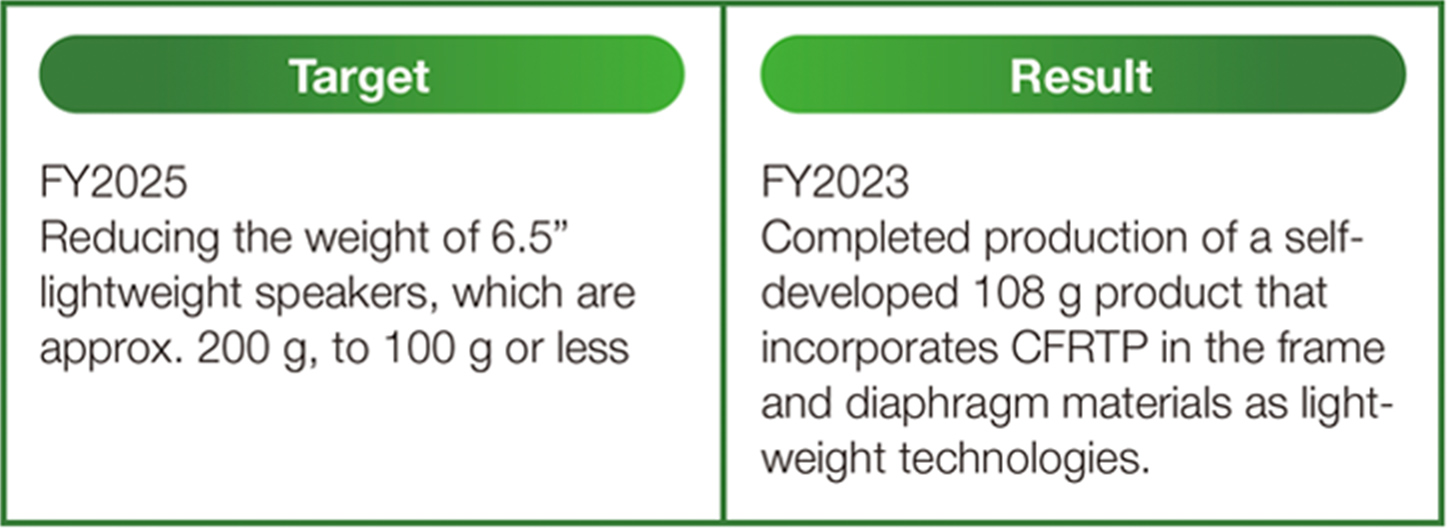

We are accelerating moves to develop basic technologies for next-generation speakers for eco-friendly vehicles and to introduce such technologies to commercial products.

Reduce the weight of speakers

We are using CAE analysis to optimize the design of resin and metal components and study carbon fiber reinforced thermoplastics (CFRTP) as new materials. We are also working to commercialize self-developed products, incorporating lightweight technologies to address concerns related to EVs, particularly extending their range and improving their power consumption efficiency.

Speakers developed with weight reduction technologies

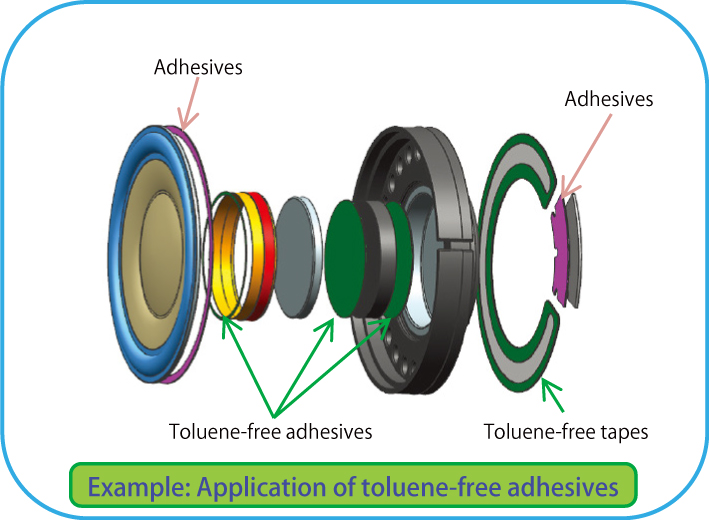

Reduction of volatile organic compounds (VOCs)

As initiatives to reduce the volume of VOCs remaining at production sites and in the passenger cabins of vehicles, we have cut the use of organic solvent adhesives for bonding parts and drive the development and adoption for commercial products of an adhesive with a reduced solvent content. We are also committed to the development of bonding methods which do not use adhesives, such as ultrasonic welding.

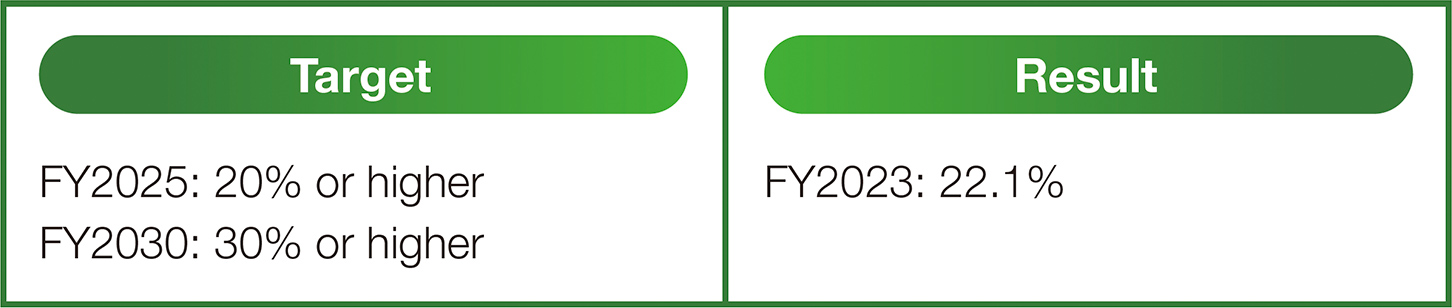

* We will continue development and introduction with a target of achieving 30% as the ratio (to net sales) of commercialized car speakers incorporating these environmental technologies.

Reduction of CO2 emissions

We are undertaking design development activities for reducing power consumed in manufacturing speakers to cut CO2 emissions. We are making development efforts to achieve the medium-term CO2 emissions reduction target, by improving and changing methods of bonding parts and by reducing the use of a drying furnace in stages.

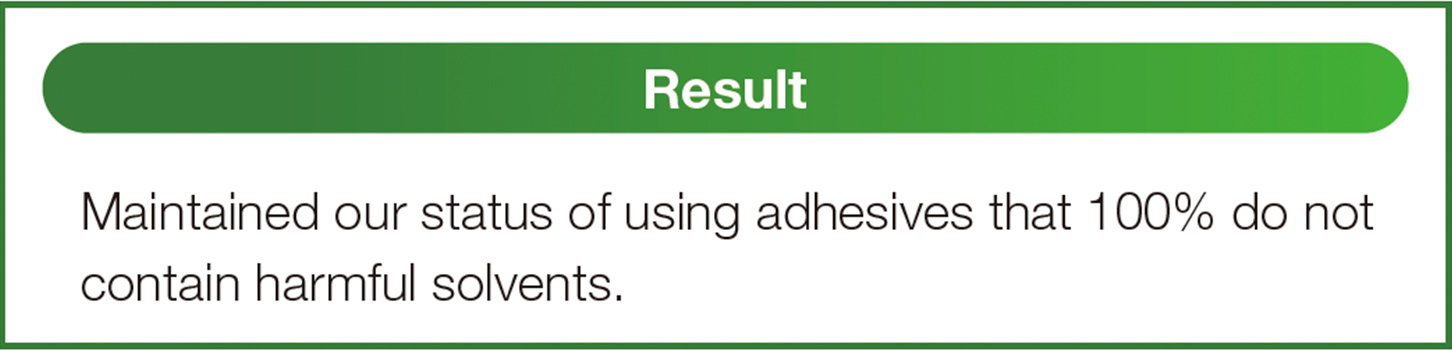

Actuators

We proactively apply environmentally friendly design to haptic vibration actuator devices, which are a part of new user interfaces for CASE*, VR, AR, and other technologies. In consideration of VOC emissions, we have adopted adhesives that do not contain harmful solvents. To reduce the labor necessary to manufacture products, we have realized quick curing using UV radiation and pulse heat soldering. In addition, to reduce solder consumption, we have developed resistance welding, etc. and put it to practical use.

* CASE: Connected, Autonomous, Shared, Electric

Automotive actuator featuring slim dimensions

Headphones and Headsets

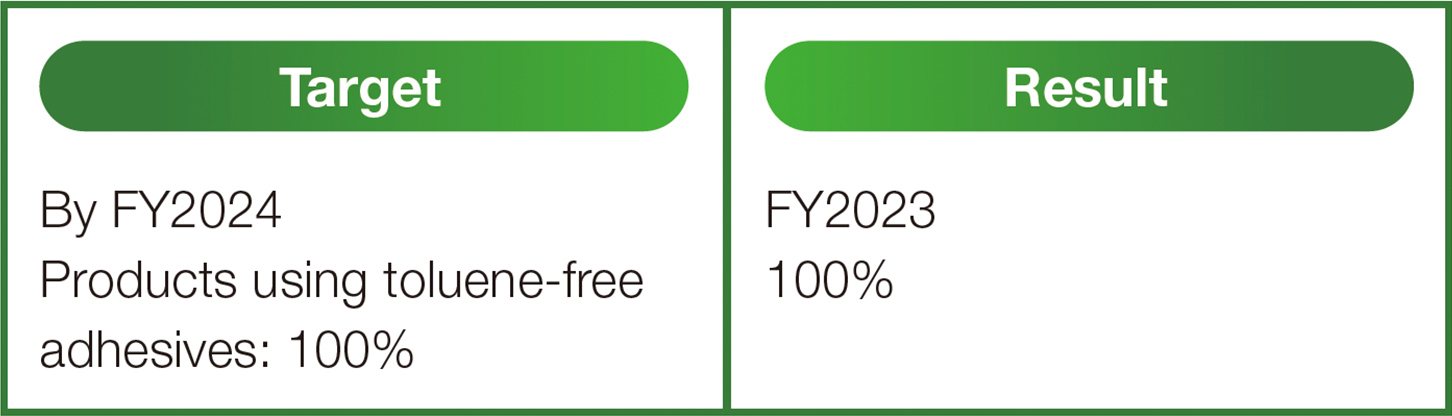

We have been active in incorporating environmental considerations in our product and/or process design. In reducing environmentally hazardous substances in our products, we address the most up-to-date information regarding country-specific legal requirements and the RoHS2, and propose to our customers. In addition, to reduce the energy consumed during manufacturing and the volume of waste materials, we need to continue to minimize waste materials, reuse raw materials by introducing new equipment, and develop products made of natural materials. For products with electronic circuits, we have adopted power-saving parts in our efforts to develop products with low power consumption. For microspeakers used for headphones or headsets, we are working towards environmentally friendly product manufacturing by introducing adhesives that do not contain toluene for new microspeakers in order to reduce VOCs. (replacing the parts that use solvent adhesives.)

As a mechanism for achieving our targets, we have built an internal system to examine whether toluene is used in the development and design phases and continue to check that products are toluene-free every month thereafter. We are also exploring alternative adhesives on an ongoing basis.

Example: Environmentally friendly microspeaker

(microspeaker with a 35 mm diameter for headphones)

Example: Product developed by using power-saving parts(Bluetooth wireless earphones)

Environment Month Activities (Headquarters)

Environment Lecture Presentation

We invited an outside expert to speak about what biodiversity is and why biodiversity needs to be protected to our officers, department heads, and group leaders (in the form of a Web conference). The lecture served as an opportunity to think about issues that we should address.

Other activities

We created opportunities to think about environmental initiatives from different perspectives through activities such as asking people to submit photos of the natural environment around them and providing environmentally friendly lunch menus.

Headquarters: Akishima City Cleanup Movement (Mini-Clean Activities)

Despite the many times these activities have been postponed or cancelled and the many employees working from home due to the COVID-19 pandemic, the annual number of participants increased by as much as 17.4% from the previous fiscal year, to 162 (participation rate: 30.7%). The total weight of waste increased to 43.47 kg. In addition, junior high school students were able to participate in the activities through a work experience program. This fiscal year, we also plan to participate in the city cleanup campaign of Akishima City.

Mini-clean activities

Environment Month Activities (Overseas)

China

We performed cleanup activities around each plant to raise employees’ awareness on environmental protection.

Cleanup activities

Vietnam

We cleaned up the neighborhood, undertook planting activities on the premises, and provided environmental training internally.

Planting activities

Training activities

Beach cleanup

Neighborhood cleanup activities

Myanmar

We provided training, undertook planting activities on the premises, and volunteered to clean up the neighborhood.

Volunteer neighborhood cleanup activities

USA

We undertook planting activities on the premises and donated used cardboard to nearby elementary schools as crafting materials.

Planting activities

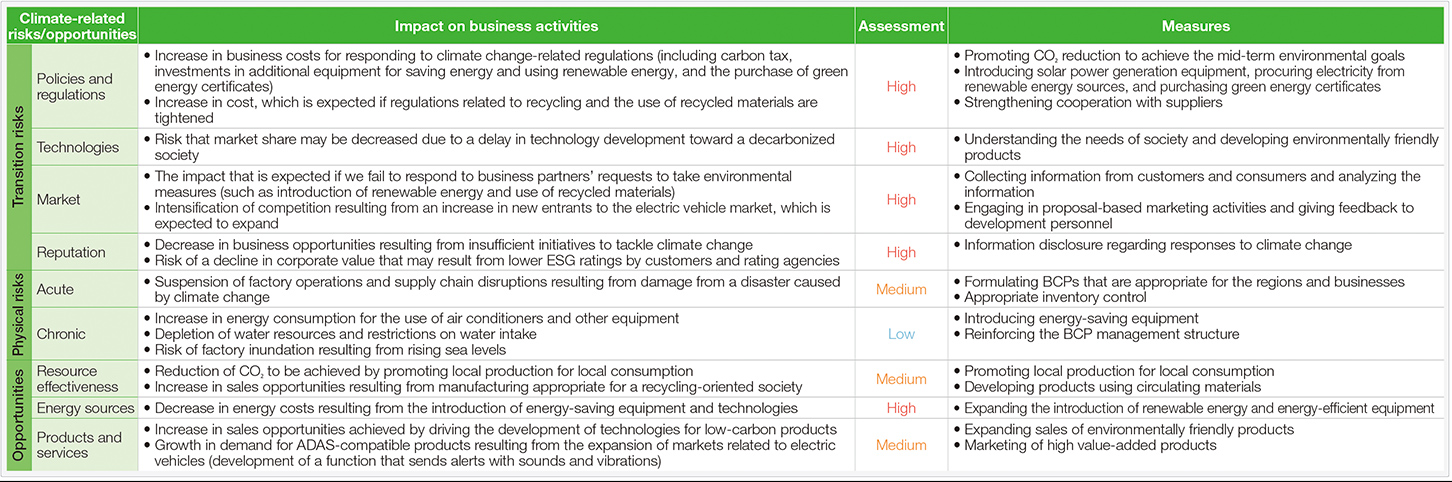

Information Disclosure Based on the TCFD Recommendations

Recognizing the importance of topics related to the environment and climate change, we declared our support for the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD*) in February 2022. At the same time, we joined the TCFD Consortium, where member companies, financial institutions, and other entities discuss effective information disclosure and appropriate initiatives following the TCFD recommendations.

We will identify our climate change-related risks and opportunities and then continue to drive effective measures by leveraging internal and external knowledge. At the same time, we will disclose information proactively by following the TCFD recommendations.

*Task Force on Climate-related Financial Disclosures: This task force was established in 2015 by the Financial Stability Board (FSB), which comprises central banks, financial authorities, and international organizations from all over the world. It is aimed at considering how to estimate the impact of climate change on business management and how to disclose such information. It recommends that companies and other entities disclose information about climate change-related risks and opportunities.

1.Governance

Viewing sustainability as an important theme, we announced our ESG Management Statement in March 2021. We set goals of achieving a decarbonized society and zero emissions in 2050 as part of our materiality (priority issues). These goals and reduction activities have been shared by all employees and are being driven by them.

The Sustainability Committee, which is chaired by the president, meets every month for the purpose of driving ESG management. This committee meets with the attendance of the sustainability officer, heads of divisions, and persons responsible for the promotion of sustainability activities appointed by departments of the headquarters and overseas bases. It identifies climate change-related issues, deliberates on and determines related policies and measures, and shares and monitors their progress.

The Board of Directors deliberates on and makes decisions on announcements of support and information disclosure related to TCFD concerning management issues, as well as reduction targets, measures, and other matters. It also receives reports on deliberations and progress made by the committee, regularly and as needed, thus supervising the committee's execution of operations.

2.Strategy

Under the framework advocated in the TCFD recommendations, we considered changes in the external environment in 2030 and analyzed the impact of climate change on us.

We adopted the 1.5-degree and 4-degree scenarios for analyzing risks and opportunities. Regarding transition risks, we considered how policies and markets will change for the alleviation of climate change. Concerning physical risks, we also analyzed how the frequency and impact of climate change-related weather disasters will change.

We reflected the identified risks and opportunities in the medium-term business plan. Moving forward, we will also consider the financial impact on the Company. We are conducting an analysis of the part of the automotive business, which is subject to a significant impact. We will continue the analysis by focusing on other businesses as well.

Impact on Business Related to Climate Change Risks and Opportunities

・Target business: Automotive as the Company's main business

・Level of impact on business activities: Evaluated on a three-point scale of Large, Medium, and Small

[Scenarios that were used]

Transition risks: International Energy Agency (IEA)(*1

・World Energy Outlook 2022:APS(*2, STEPS(*3

・Net Zero Emissions by 2050 Scenario(*4

Physical risks: Intergovernmental Panel on Climate Change (IPCC) (*5

・6th Report: SSP1-1.9, SSP5-8.5 (*6

*1. IEA: International Energy Agency

*2. APS: Announced Pledges Scenario

*3. STEPS: Stated Policies Scenario

*4. NZE: Net Zero Emissions by 2050 Scenario

*5. IPCC: Intergovernmental Panel on Climate Change

*6. SSP: Shared socioeconomic pathways

3.Risk Management

We have established the Risk and Crisis Management Committee, which is chaired by the president, to ensure that risks which may affect business management are addressed promptly and appropriately. This committee evaluates and manages company-wide risks and devises and implements measures to address them.

Especially, climate change-related risks are positioned among the top risks in the committee's total risk assessment. The Sustainability Committee identifies and evaluates such risks, implements measures to tackle them, and takes other initiatives to improve the effectiveness of risk management.

Information about the statuses of risk management and measures is also shared with the Board of Directors, which supervises and monitors risk and crisis management of the overall company and tries to ensure consistency between risk management and materiality analysis, thus enhancing the total risk management in the entire company.

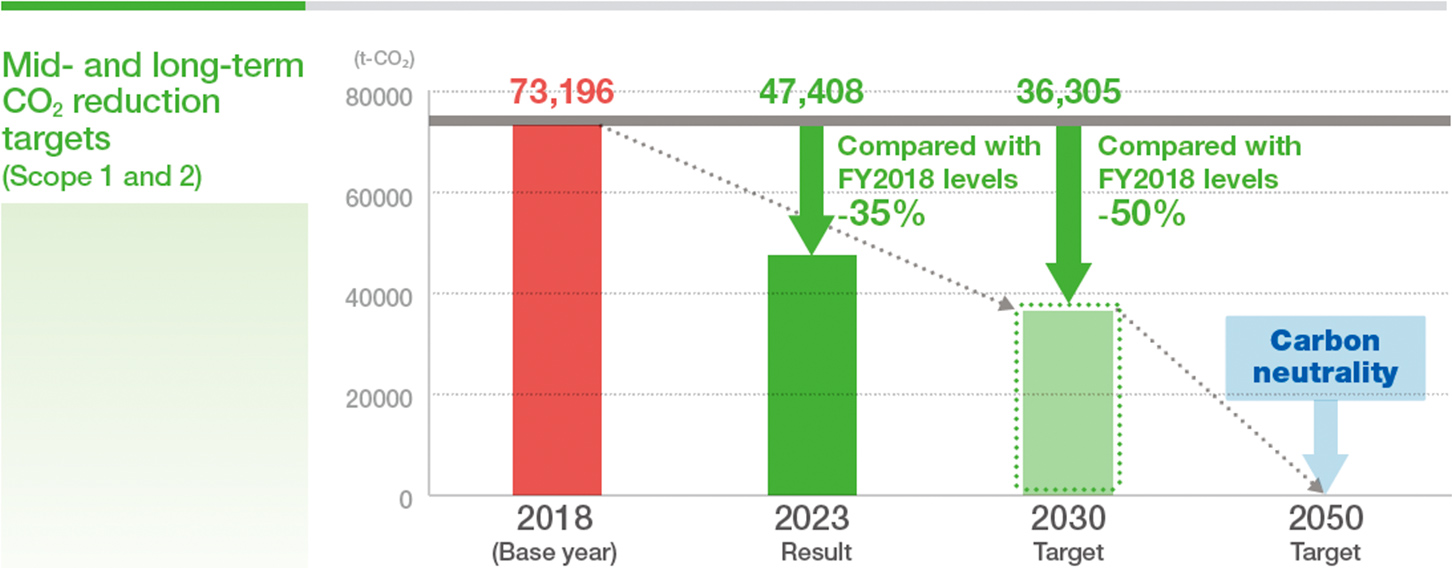

4.Metrics and Targets

Toward the achievement of sustainability, we have established the Foster Group ESG Management Statement in March 2021, under which we aim for “Decarbonized Society” and “tireless efforts to achieve Zero Emissions” in the medium and long run. Under this Statement, we have revised our mid-term environmental goals for 2030 (Scope 1, 2) in line with the 1.5-degree goal of the Paris Agreement. We have also set a new long-term goal for 2050.

1. Mid-Term Reduction Goals for 2030

・Scope1、2:Reduce absolute CO2 emissions 50% by 2030 from a 2018 base-year

・Scope3:Reduce absolute CO2 emissions 15% by 2030 from a 2018 base-year

2. Long-Term Reduction Goal for 2050

・Aim to achieve carbon neutrality by 2050

To achieve this goal, we have developed the CO2 Reduction Action Program [Ver. 2024]. The headquarters and the other sites will work together in accelerating CO2 reduction activities in a group-wide manner.

3. Specific Reduction Measures

1. Our own power-saving efforts (steady efforts and innovative activities)

【Steady efforts】

Specific measures:

・Operational improvements: Improvements of operation, maintenance, heat retention, heat insulation, etc.

・Introduction of energy-saving equipment: Remodeling or replacing equipment

【Innovative activities】

Activities:

・Studying and introducing new manufacturing methods and design specifications Specific measures:

・Developing innovative technologies through a next-generation speaker project, etc.

2.Renewable energy procurement

・Switching electricity purchased from electric power companies to an option with 100% renewable energy sources

3.In-house power generation from renewable energy sources

・Introducing equipment for in-house solar power generation

4.Purchasing green energy certificates for offsetting (shortfalls)

・Purchasing green energy certificates for overseas factories

4. Specific KPIs

・Setting “Power consumption ÷ Net sales” at each site as a KPI for power-saving activities

・Having each site set a goal of building a framework, which makes it possible to post the same amount of net sales with 4% less power consumption than the actual power consumption in fiscal 2023, by the end of 2024. We will achieve the interim goal for fiscal 2025 (30% reduction from a FY2018 base-year), aiming to surely achieve the fiscal 2030 goal (50% reduction from a FY2018 base-year).